In addition to transmitting heat, sound or electricity, electrical coils are required to perform several different functions. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Dufrane is an industry leader in the design and manufacture of electric coils. Whether we provide individual electrical coils or combine coils into 3-phase step up or step down transformers, we can accommodate the coil needs for your products, including design, build to print and reverse engineering older designs. Contact us now for more information.

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Electrical Coil Manufacturers

The many attributes of electrical coils enable them to meet a wide range of application requirements for industries including: industrial manufacturing, which utilizes many molded coils or encapsulated coils for protection against corrosive environments, and electrical solenoid coils for remote equipment; automotive, in which induction coils, such as ignition coils, are essential for the operation of internal combustion engines; electronics, for equipment and devices such as electric transformers, radio transmitters, cameras and strobe lights; medical, for use in imaging and therapy equipment; and power generation, which often use high voltage electrical coils for supplying power to warehouses and other industrial, commercial and residential buildings. In addition to transmitting heat, sound or electricity, electrical coils are required to perform several different functions.

In order to better fit the specifications of the broad spectrum of applications they are used in, there is a multitude of electrical coil types that differentiate in terms of wire gauges, coil diameter wire lengths and core materials. All of the coil specifications can be customized to meet diverse requirements.

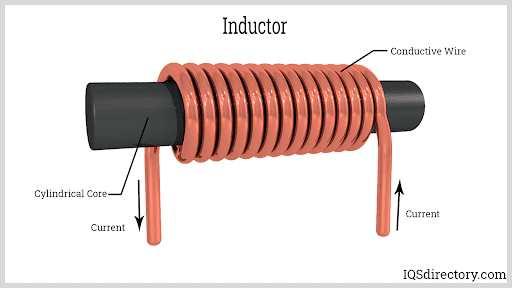

The basic construction of an electrical coil is typically that of its core, a primary coil and a secondary coil. However, this simple design can quickly become complicated with the addition of more coils, which are also referred to as windings. A winding is defined as a complete coil assembly with taps that are used to connect to current flow either from an input or to an output.

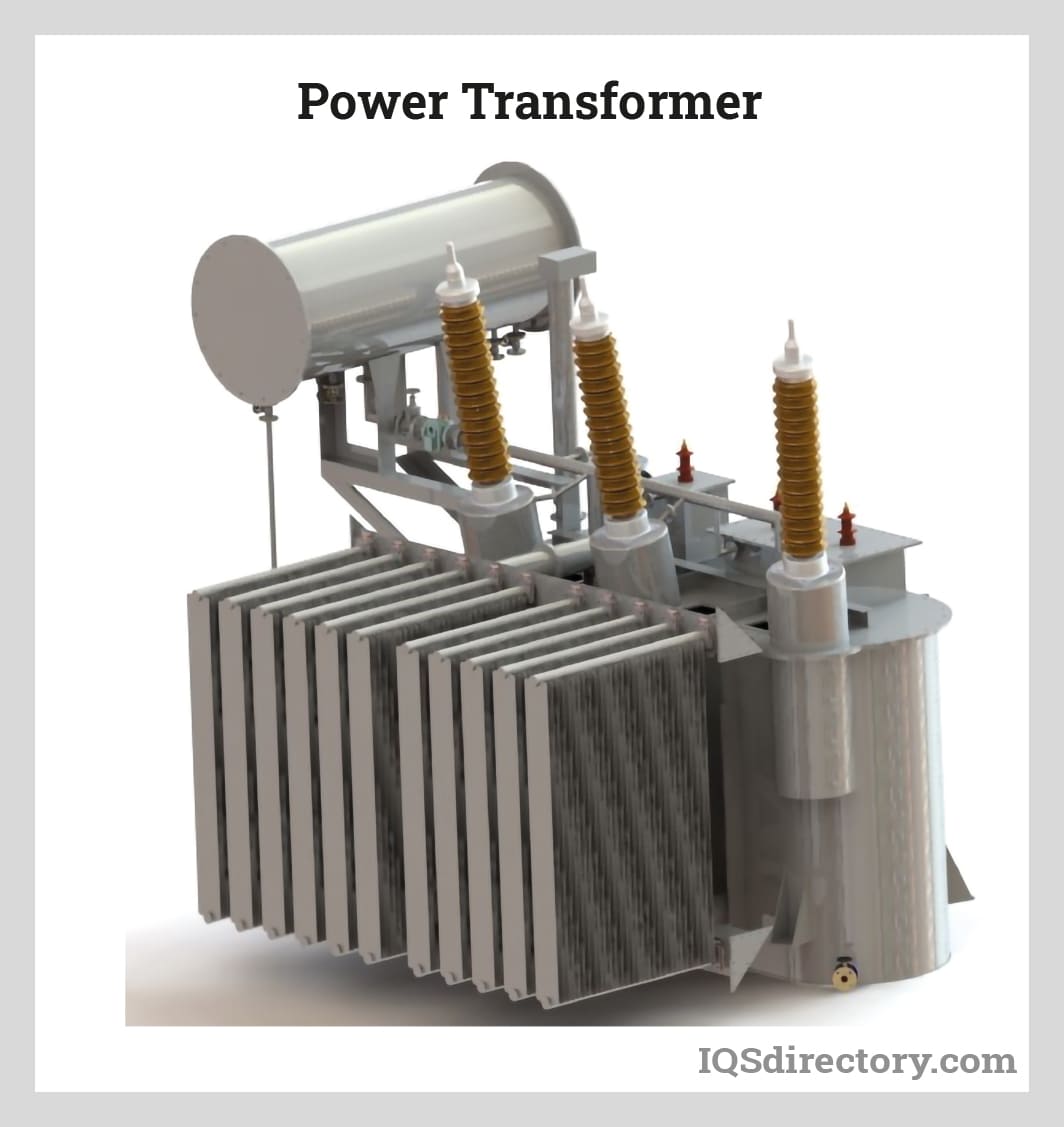

While just one primary winding can be used at times, most applications require the addition of secondary winding, and some can even require tertiary windings (which are known as tickler coils). An electric transformer, for example, is an electrical coil that has a primary and a secondary winding, enabling it to transfer electrical energy from one electric circuit to another electric circuit without any moving parts. Not only does the number of windings affect the function of the electrical coil, but the coil taps can as well.

Coil taps are defined as points in the wire coil that consists of an exposed conductive patch and mostly differ in size. For example, when an electrical coil has a large diameter, the amount of self induction is similarly large and the current can become problematic. It will try and flow on the inside of the wire instead of on the outside.

Another example would be that of multi-layered electrical coils, which have issues with interlayer capacitance, defined as an electrical phenomenon whereby an electric charge is stored, requiring a spiral-shaped coil.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services