Electric coils, are a type of electrical conductor, wound in the shape of a coil, a helix, or a spiral. Their primary function is to transmit sound, heat, or electricity. Electric coils are also known as magnetic or electromagnetic coils. This terminology can cause some confusion since the term electromagnet can specifically refer to electric coils which directly affect an external object through its magnetic field. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

At Dufrane Technologies, we take pride in our extensive range of electric coils. Our comprehensive product portfolio encompasses a wide variety of coil types, including solenoid coils, electromagnet coils, induction coils, and more. Whether you require custom-made coils or standard options, we have the expertise and resources to fulfill your specifications with precision.

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Electric Coil Manufacturers

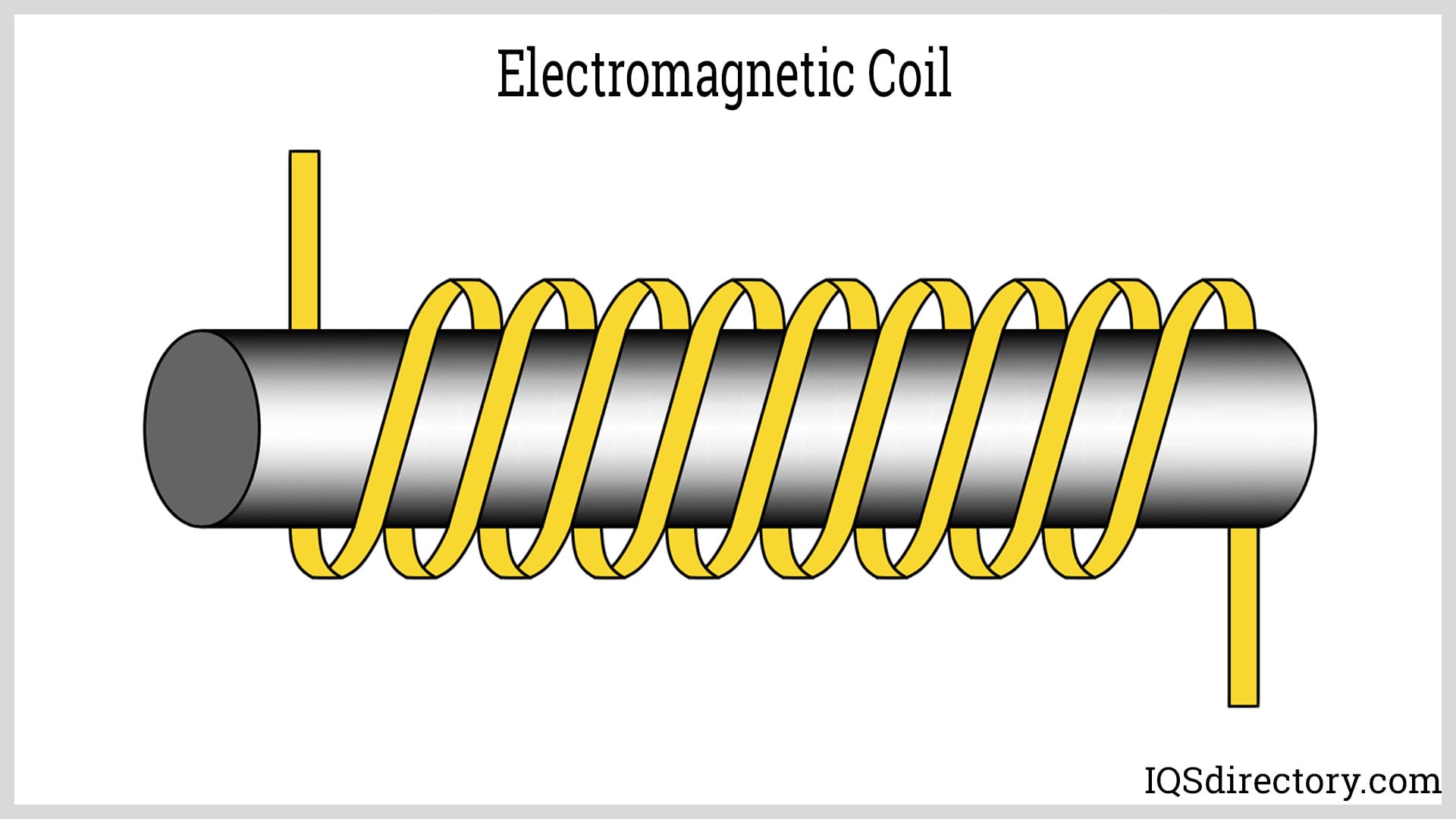

This in contrast to other types of electric coil, such as one designed primarily for producing heat. However, since all electric currents in a conductor produce magnetic fields, the electromagnetic coil is technically accurate. An electric coil works either when electric current passes through it and generates a magnetic field, or when a time-varying magnetic field outside of it generates a voltage that passes through its interior.

A Brief History of Electric Coils

Since electromagnetism is the scientific basis of (most) electric coils, the origin of electric coils can justly be traced to the discovery of electromagnetism in the first half of the nineteenth century. The French scientist Andre-Marie Ampere (who lent his name to a common electrical unit) discovered electromagnetism’s ability to induce movement in 1820. Other scientists continued to build upon Ampere’s discoveries, including English scientists Michael Faraday, English scientist William Sturgeon, and American scientist Joseph Henry. These scientists’ further discoveries formed the basis of electric motors by harnessing and directing electromagnetic power in the form of electric loops, or coils. Joseph Henry also contributed to the development of electromagnetism by pioneering electromagnetic relays (electronically controlled switches) in 1835 and later applying them to his most famous invention, the electric telegraph. (The American Samuel Morse was responsible for further development of this invention.) Electromagnetic relay coils were critical to early telecommunications (telegraphs and telephones) and computer models; they only began to lose their prominence when electronic transistors appeared in the 1940s. Although transistors are widespread today, electromagnetic coils are still preferred for transmitting larger electric currents.

How Electric Coils Work

Though they serve wide-ranging applications, almost all electric coils share the same basic construction and electromechanical principles. Electric coils are formed when a conductive metal wire is wound around an insulator. The entire wire is known as the winding while each individual loop in the winding is known as a turn. A hole exists in the center of the coil; this region is called the core area or the magnetic axis. Typically, the two ends of the wrapped wire are converted into electrical connection terminals called “taps.”

Power is created when the taps are linked to an electric current which moves through the coiled wires and magnetize the coil. (Occasionally, the current performs the opposite function and demagnetizes the coil.) This is possible because flowing electric currents create circular magnetic fields present all along the length of the conductor. Coiled electric conductors create stronger magnetic forces than straight conductors since they produce similar magnetic fields which merge in the center of the loop. Electric coils, which are composed of multiple individual electric loops wound around the same axis, can produce very strong magnetic fields. The core magnetic axis serves to concentrate this combined magnetic flux. Some coils are made with coil taps, which are exposed conductive patches at various points along the wire coil. These taps function as additional electrical connections and can vary widely in diameter and frequency. Coils that have just one tap placed at their center, for example, are described as “center-tapped.”

Electric Coil Materials

While there are many conductive metals, the ones most often used to make electric coils are aluminum and copper. Electric coils designed for heating purposes usually consist of a nickel or iron alloy. With regard to the insulator, it may be made from a number of diverse, non-conductive materials, including plastic, enamel, cardboard, or even air. Coils are often insulated in some way, mainly to prevent current from flowing between coil turns and to shield coils from prolonged exposure to corrosion or damage-causing conditions like salt, moisture, oil, or vibration. Coils can be protected in a variety of ways: Encapsulation applies only to the wire of coils; encapsulated coils consist of wire that has been covered in a polymer epoxy. Molded coils, on the other hand, are encapsulated in plastic coverings that seal not just wires, but the entire winding. Other electric coils, like toroid transformer coils, are protected from environmental exposure by sealing tape.

Customizing Electric Coils

In addition to varying by material composition, coils can vary wildly in diameter, wire lengths, wire gauges, depending on their application requirements. Some general rules can serve to guide coil customization. As a rule, the larger the coil diameter, the greater the amount of self-induction it exhibits. (While this can be helpful, it can also be problematic, as current trying to flow on the inside of the wire often flows on the outside instead.) In addition, stronger magnetic fields can be produced by one of two methods. Since the strength of an electromagnetic field is directly related to the amount of current and the amount of turns in an electric coil, increasing either feature increases the coil’s magnetic strength. Furthermore, the strength of the electromagnetic field (also known as magnetic permeability) can be strengthened by changing the core of the coil. Hollow cores (consisting of air) or cores consisting of ferromagnetic material (material which can be magnetized) produce stronger magnetic fields than cores made of material such as plastic. Ferromagnetic material used for this purpose includes soft iron, various types of steel, and nickel alloys.

Types of Electric Coils

Aside from the shared basic features that were previously described, electric coils have many variations. Electric coils can be classified by the type of current they carry (e.g. direct current, alternating current, etc.) More commonly, electric coils are categorized according to their function. As alluded to previously, electromagnets are electric coils specifically designed to exert a magnetic force that can be harnessed for a practical application. Often, this application is mechanical; the interaction of like magnetic fields in the center of electric loops and coils produces a strong force that can be translated into motion. The most basic type of electric coil consisting of several loops wrapped around an axis is known as a solenoid coil. These coils serve a variety of uses; one of the most common uses is remote switching (to be described further below), as they carry currents through the coil and produce magnetic fields which attract and move switches.

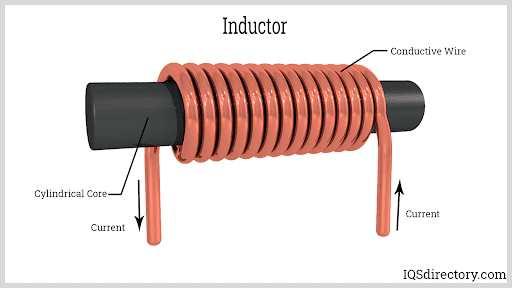

A common, more advanced type of electric coil is one that is equipped with extra windings. An electric coil that has multiple windings is known as an electric transformer. (As alluded to before, the term “winding” simply refers to a complete coil assembly rather than an individual loop of electric wire.) The first winding of an electric coil is called a primary winding, while a second winding is called a secondary winding and a third winding is called a tertiary winding. (Electromagnetic components which have a tertiary electric coil are called tickler coils.) Electric coils with multiple windings are usually electrically insulated and share a common magnetic axis; if the latter is the case, the windings are labeled as being magnetically coupled or inductively coupled. Transformers connect electric currents through a “domino” effect; when an electric current is applied to the primary winding, it creates a time-varying magnetic field which triggers time-varying voltage in the other windings. This voltage can be varied by altering the number of individual turns within the various windings. Because of this, transformers are primarily used to vary the voltage in electric circuits. Some transformers possess steel cores (divisible into laminations) to reduce energy loss and reside in cooling oil to control energy loss produced as heat. High voltage transformers are often known as power transformers while low voltage versions are known as distribution transformers. Other broad categories of electric coils exist. One family of coils, inductors, consist of “reflexive” types of coils designed to exert magnetic fields on themselves (e.g. to oppose electric current changes). Transducers refer to any type of device that translates input in a certain physical form into a different type of output; with reference to electric coils, they often refer to devices which translate magnetic fields into electric signals.

Applications of Electric Coils

Electric coils come in many forms and serve a diverse set of applications. Fundamentally, they are used to power electronic devices through the production and application of electromagnetism. Many types of electrical circuits could not function without transformer coils, choke coils, and similar devices. Electric coils are found in a wide range of industries, including manufacturing industry, the automotive industry, the electronics industry, the medical industry, the energy industry, and more. In the automotive industry, induction coils, also called ignition coils or spark coils, power the ignition systems of cars, vans, and trucks. Next, electric coils power the functions of important equipment like MRI machines. In addition, power plants rely on electric coils such as high voltage coils and toroidal coils to help with power generation. Also, in general, electric coils regulate flow, produce movement, and/or transform electric currents in applications relating to computers, appliances, and telecommunications. Electric coils, which are highly customizable, may be designed for unique applications or certain environments. Rogowski coils, for example, are used exclusively to measure alternating current (AC), while Braunbeck coils are used in geomagnetic research. Also, Oudin coils provide a disruptive charge and Garrett coils are made specifically for use with metal detectors.

One of the most common applications of electric coils is their usage in electric relays, or electronically controlled switches. Relays are widely used for their ability to control larger currents with smaller currents through an ingenious translation of magnetic force into mechanical force. When an electromagnetic coil in a relay produces a magnetic field, it is able to mechanically move a switch within a larger electric circuit through magnetic attraction. The switch is designed so that it connects electric contacts within the larger circuit once it moves according to the electromagnetic force. Using this principle, electromagnetic coils are able to power appliances which depend on the larger circuit, such as a lamp. Relays themselves are often part of various electric motor systems, which translate electric flow into rotational motion. Electric motors can power a wide variety of appliances, including common household items such as fans, mowers, toys, toothbrushes, etc.

Electric coils are also used to produce heat and sound as well as motion. In heating applications, the coiled shape of the conductor is more incidental than intentional, since heat depends primarily on the amount of electric current rather than the shape of the conductor itself (in contrast to strict electromagnetic applications). Most often, heating coils are designed as coils in order to fit into particular applications, such as stovetops. However, it is important to note that various aspects of the coil design (e.g. material, wire diameter, length) do affect heating performance. Nichrome, a nickel alloy consisting of 80 percent nickel and 20 percent chromium, is the preferred material of choice in many heating coil or coil heater applications. Audio applications of electric coils are found in products such as speakers. As electricity is passed through the coil, it changes the direction of the coil’s magnetic field and causes it to be alternatively attracted to and repelled from a nearby magnet (which is fixed in place). This rapidly changing attraction causes the electric coil to vibrate. When the coil is attached to a flexible cone, the cone produces amplified versions of the vibration which users perceive as sound.

Advantages of Electric Coils

The main advantage of electric coils is the ability to obtain magnetic fields that are much stronger and much more controllable than magnetic fields produced by permanent magnets. Working with a coil-shaped conductor (such as a solenoid coil) both increases the strength of the magnetic field and allows for very practical uses such as remote machinery activation. The controlability of electric coils’ magnetic fields is closely tied to the ability to activate large electric currents with smaller ones (as in the case of switch relays.) Electronic transistors, although they perform many relay functions that electromagnetic coils did in the past, are still generally inferior to electric coils with regard to controlling large currents. Electric transformers have a couple of distinct advantages. Their use of primary and secondary windings allows the transfer electrical energy from one electric circuit to another via magnetic coupling without the necessity of moving parts. Furthermore, transformers are valued for making electric use more efficient. Since increasing electronic voltage reduces electronic current, transformers are able to efficiently transfer power over long distances simply by altering AC voltage.

Things to Consider for Electric Coil Suppliers

Some standard considerations apply when looking for electric coils and electric coil manufacturers. Since electric coils are highly sophisticated pieces of equipment, you should invest in electric coils made from the highest quality materials. Consider an electric coils supplier’s range of materials as well as well as their range of possible shapes; some specialty coil applications may require unusual composition or configurations. Other factors to consider are a supplier’s sampling or prototyping services, turnaround and shipping times, etc.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services