A custom coil refers to an electrical conductor made with the general purpose of converting electrical energy into linear motion but customized with specific materials required for a specific application. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

With more than 40 years of experience, Dufrane is an industry leader in the design and manufacture of custom electric coils of all types, due to our custom winding capabilities. Custom windings and coils can be designed or build to print, and we excel in standard bobbin winding, self-supporting coils, toroidal windings, as well as challenging shapes and configurations. Contact us now...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Custom Coil Manufacturers

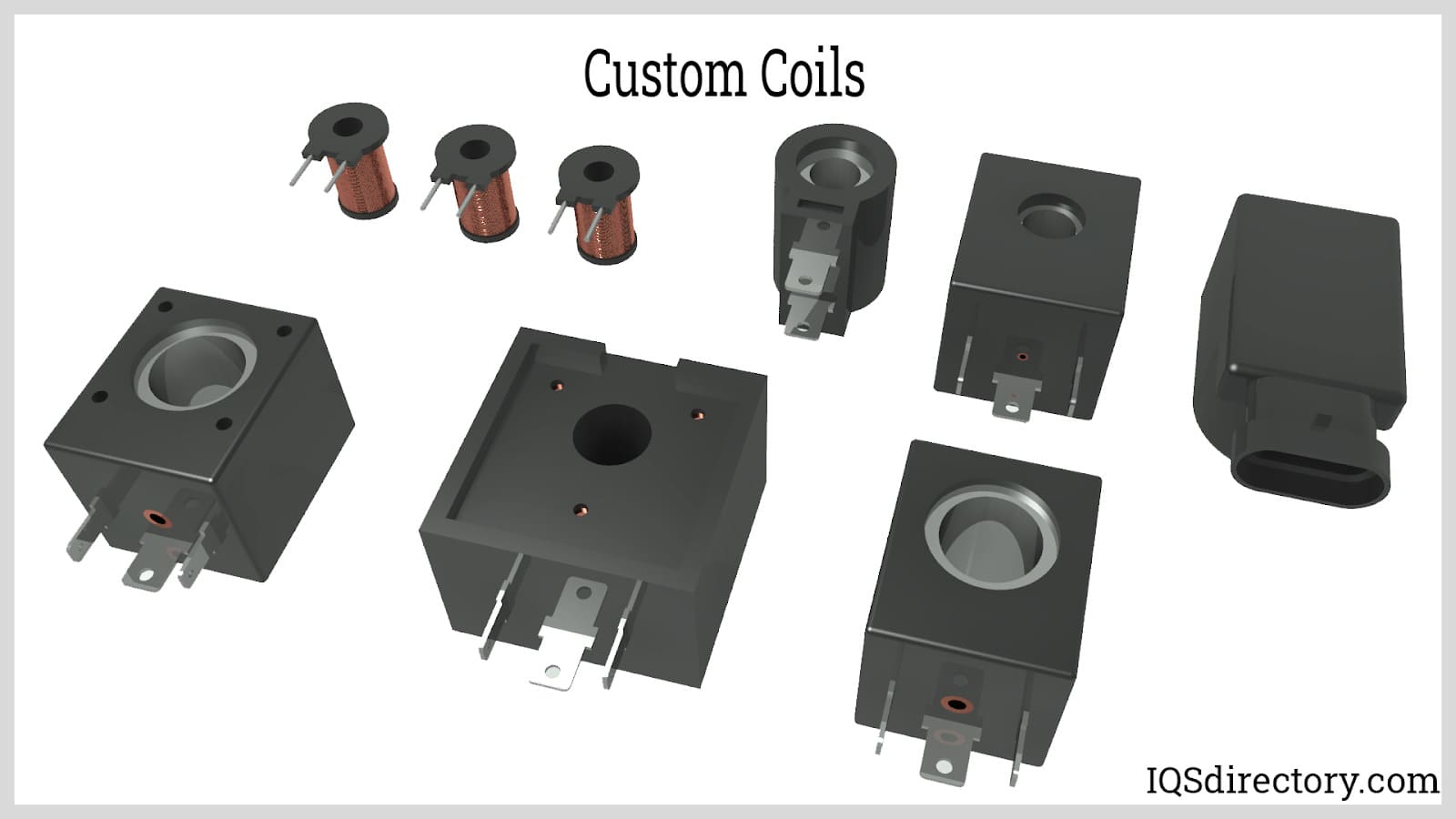

What Is a Custom Coil?

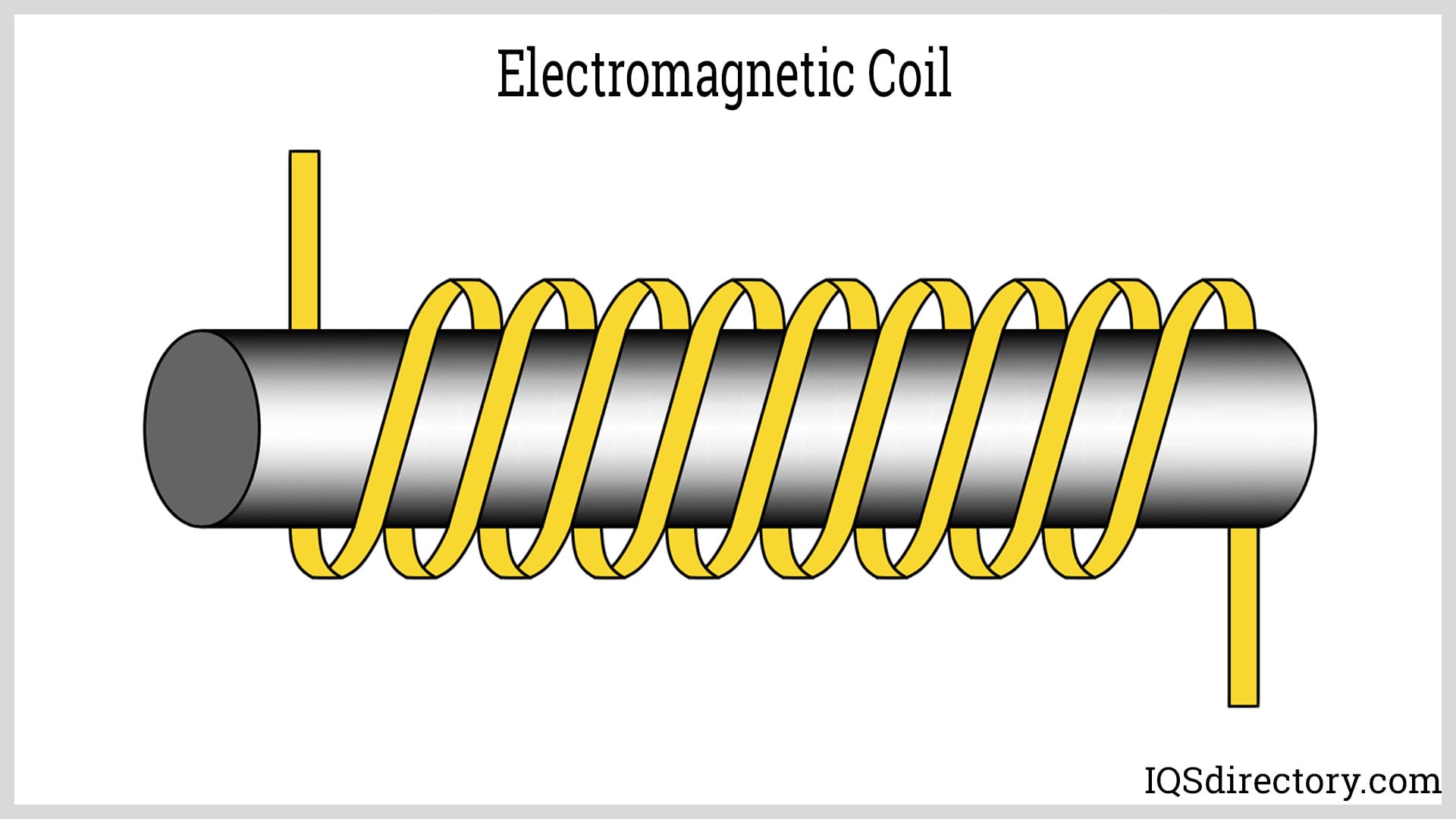

Custom coils are made considering the form material, the wire material, the wire type, and the wire coiling process. The types of wire commonly used when making custom coils include copper and aluminum. In the process of wire production, the wire can be created using processes such as single layer, multi-layer, random layer, self-bonding, dry or epoxy wound, precision winding, and manual or automated.

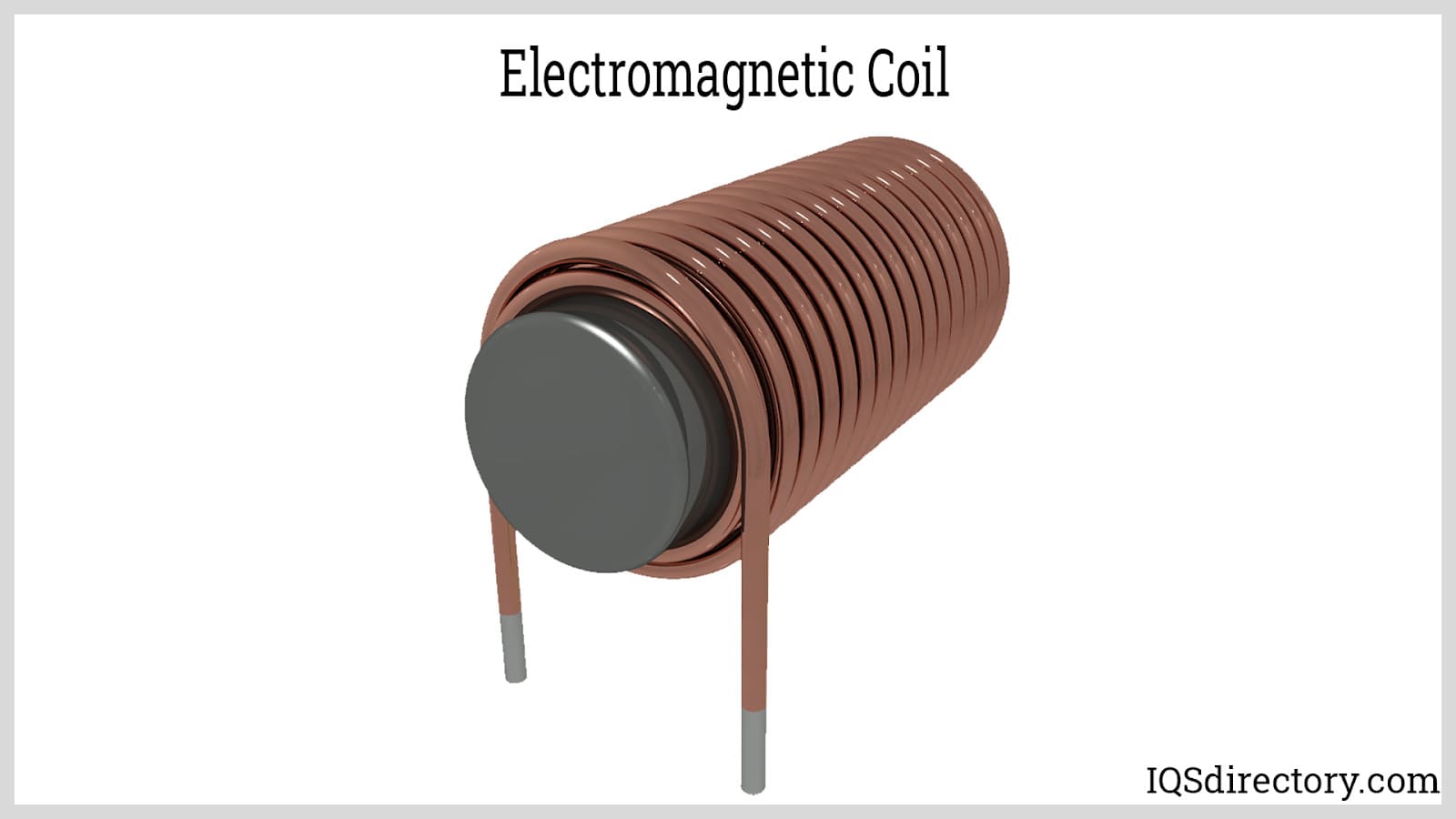

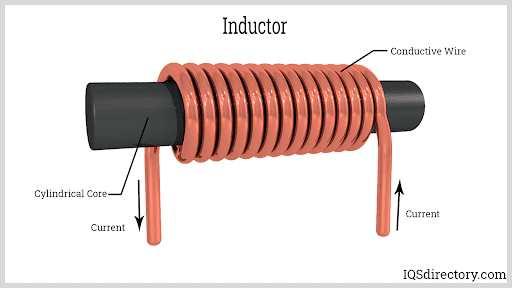

The two main types of coils classified according to their function include electromagnets, transformers, transducer coils, and inductors. The inductors are also named reactors, and they are the coils that generate a magnetic field that interacts with the coil itself to induce a back electromagnetic force (EMF). Electromagnets are used to generate a magnetic field for an external purpose, often in the generation of a mechanical force onto something.

How Custom Coils Are Made

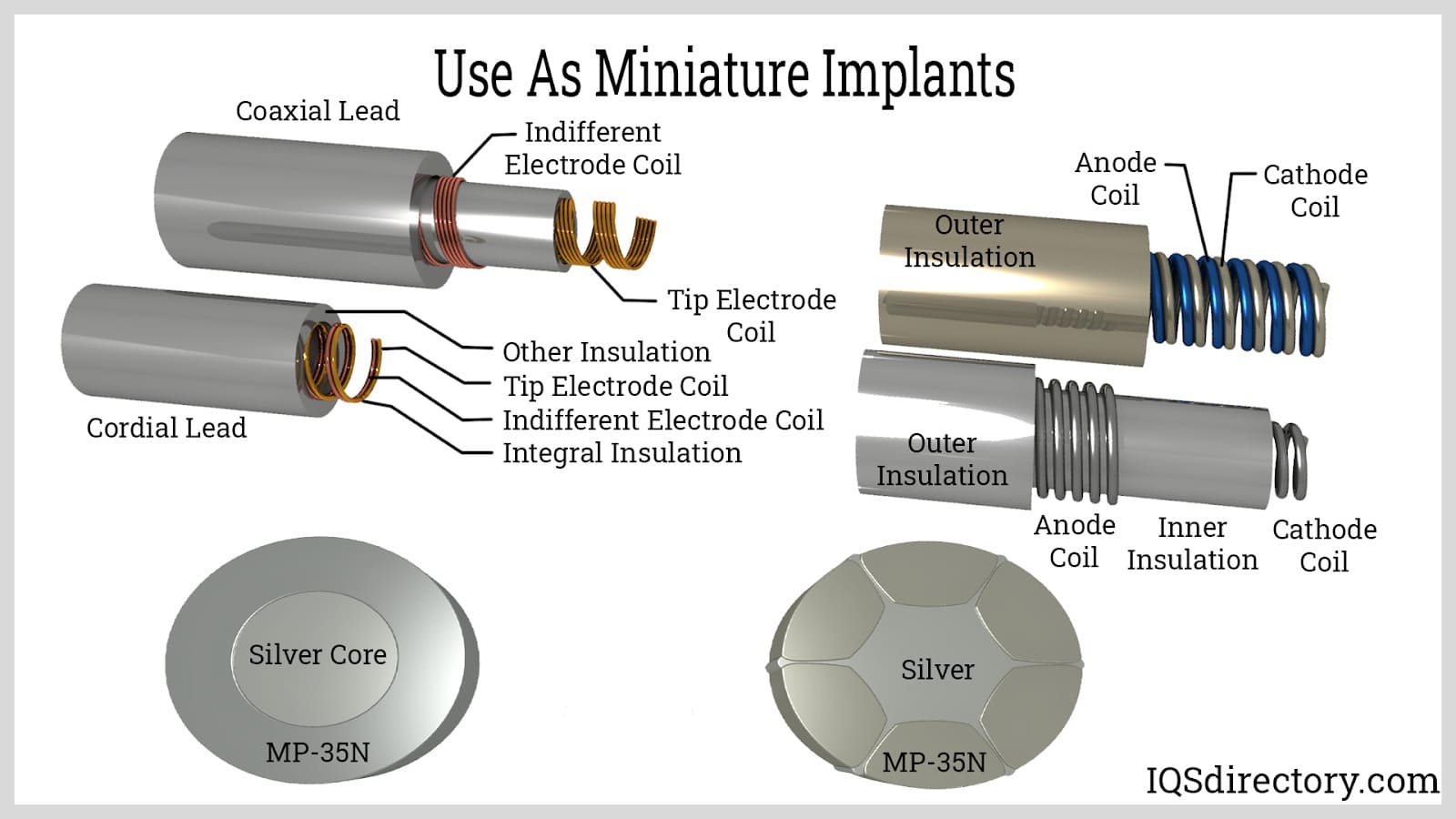

The custom winding process is used in the production of the custom coils. This process includes twisting ultra-fine wires around a contained core or pin in a round, spherical, or helical shape. However, different users may have different requirements for the shape and the size of the coils. For example, some people may require coreless coils. To manufacture these coreless coils, the manufacturer must remove the core after completing the winding process of the coils to be able to insert the coil into the vein.

Coreless coils have a great advantage since they are more effective. To produce custom coils with different thicknesses, the manufacturers change the number of windings contained around the core. These windings can be placed into classes, including single or multi-layer winding. The wires used in the production are connected, which helps ensure their protection against reaching the isolation breakpoint.

Due to its conductivity, copper is used to make most of these ultrafine wires. Different materials such as stainless steel, gold, platinum, titanium, aluminum, and titanium alloys are also used. This is because of the different applications in which custom coils are required. Ultra-fine wires are essential for preparing the custom coils, but a great challenge arises in handling them, especially in connecting two wires. This challenge can be tackled using thermal pressure bonding technology, which helps in effectively bonding these ultra-fine wires.

Types of Custom Coils

Custom coils can be grouped in relation to their wire type, area of application, wire coiling process, the shape of the coil, and the form and wire material. Coils can be grouped according to their function and the frequency of the current with which they work.

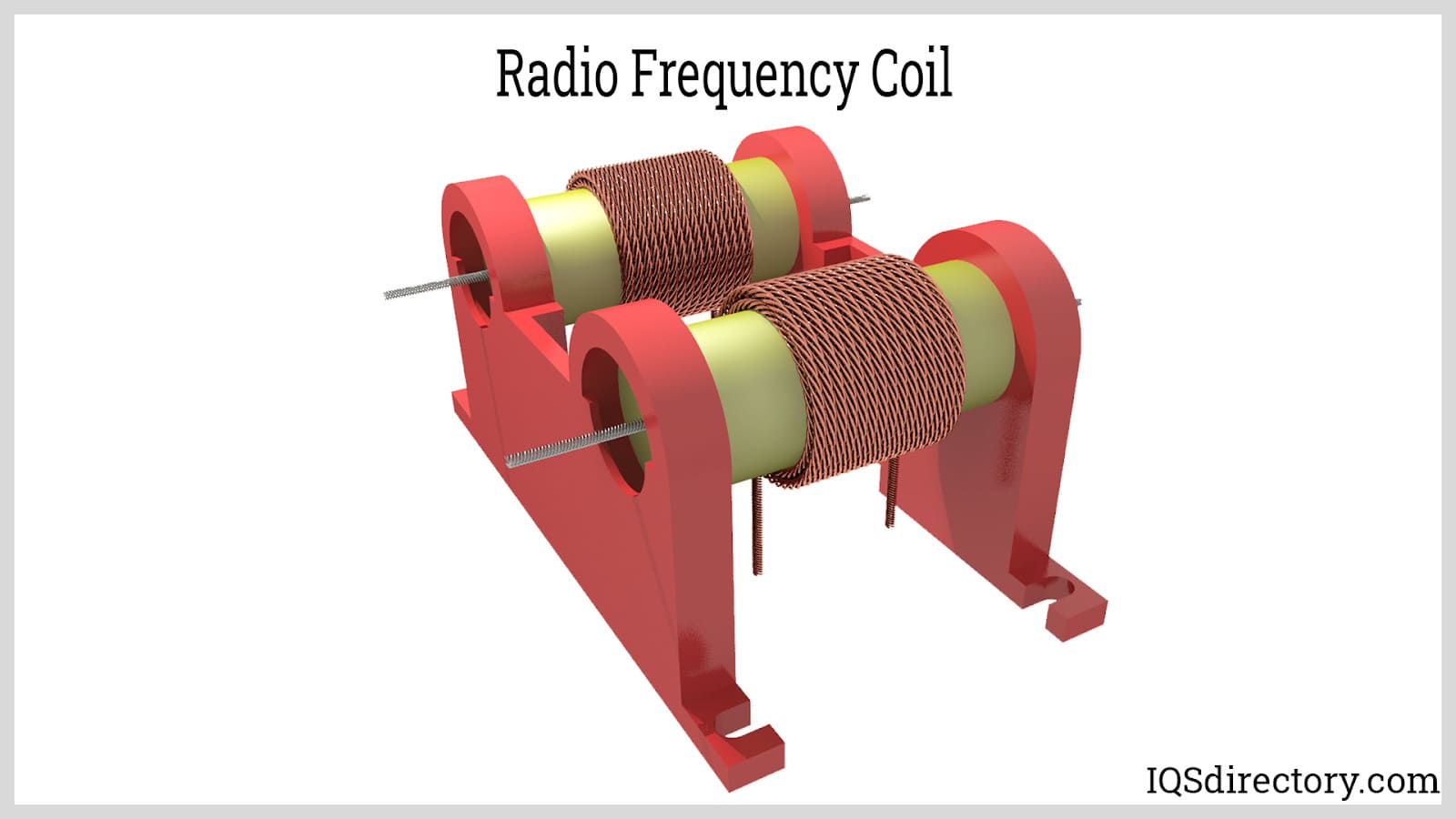

Frequency-Based Custom Coils

These coils are based on the type of current frequency they are made to work with. For example, coils may be direct current, which means that they function with a steady or direct current in their windings. Coils can also work with audio frequency, and these function with alternating currents in the audio frequency range ranked less than 20 kHz.

Function-Based Custom Coils

These types of coils include electromagnets, transducer coils, inductors, and transformers. Electromagnets are coils with a specific mandate of generating a magnetic field for external use. In contrast, inductors are used to generate a magnetic field that interacts with the coil itself to induce a back EMF.

Applications and Uses of Custom Coils

Custom coils are essential as they can be used as pain management devices and to monitor pacemakers. For electricity-based ablations, microwave and radio frequency coils are ideal. The electromagnetic custom coils are used in the dental field and other fields, including electrophysiology and orthopedic treatments.

Custom coils are also essential for the production of orientation and navigation sensors. In the medical field, custom coils can be used to produce devices such as miniature implants and medical sensors. Furthermore, the custom coils can be used in measurement instrumentation in laboratories.

Choosing the Right Custom Coil Manufacturer

For the most positive outcome when purchasing custom coils from a custom coil manufacturer, it is important to compare several manufacturers using our directory of custom coil companies. Each custom coil manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each custom coil business using our proprietary website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services