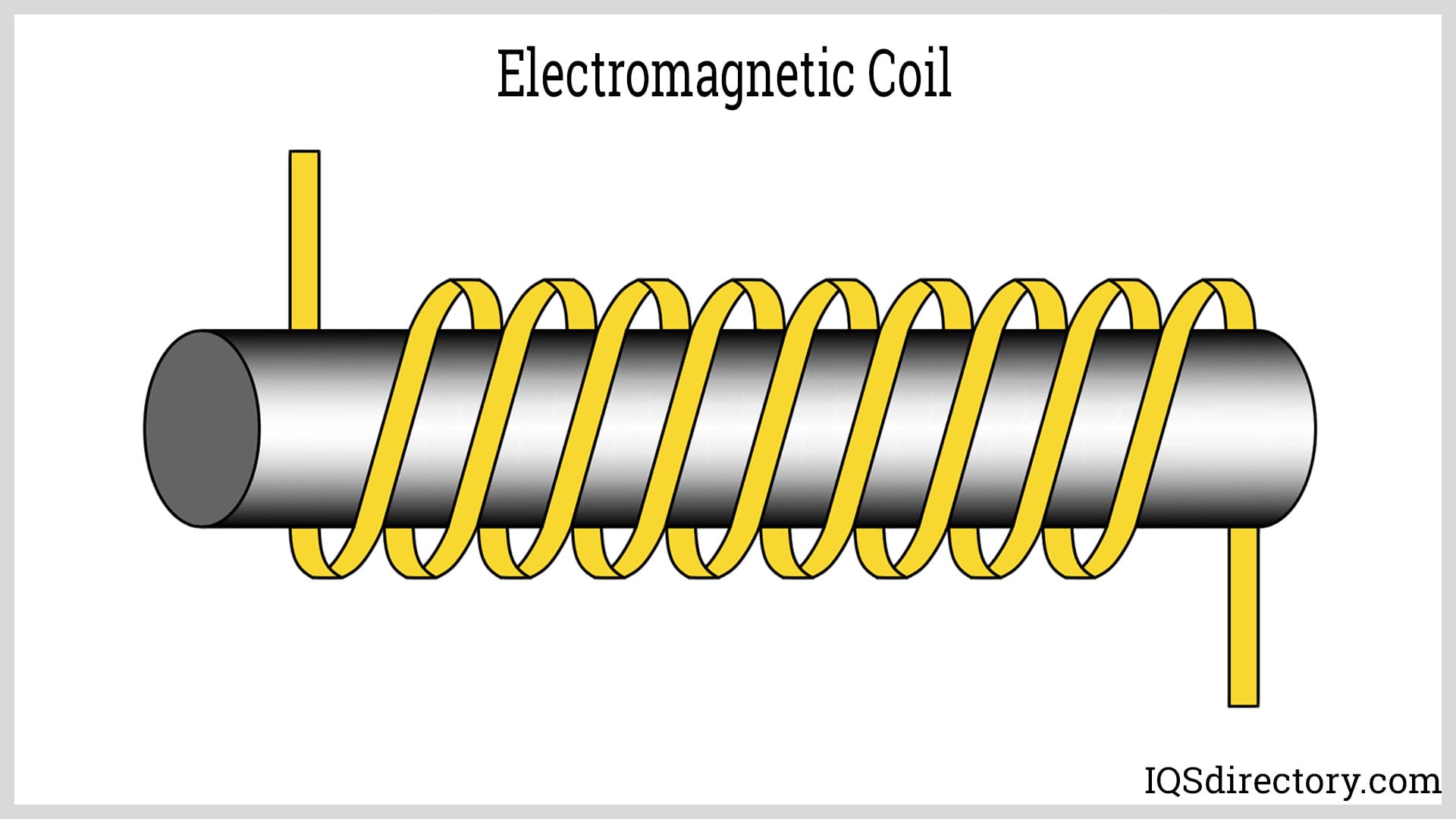

An essential part of the production of an electromagnetic field is the coil winding, which can be round, elliptical, or rectangular. The type of magnetic field produced by a winding depends on its shape and configuration. The common part of all windings is the core that is created from several types of materials. Regardless of the importance of the core, there are coil windings that do not have a core, referred to as air core windings. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Dufrane is an industry leader with over 40 years of coil winding expertise. Whether we wind on precision coil winding machines or wind complex coils by hand, Dufrane custom windings and coils can be designed or build to print. Dufrane primarily uses copper, aluminum, or copper clad aluminum wire and we work with inner diameters from 0.062” and tolerances are held to as tight as ±0.001”...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Coil Winding Manufacturers

How a Coil Winding is Made

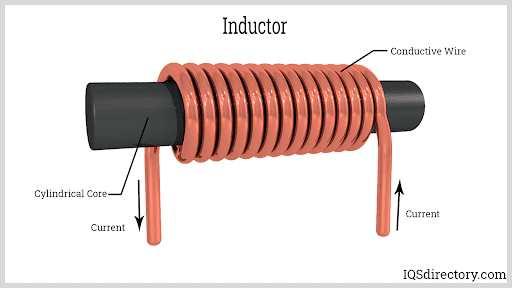

When discussing coil windings, there are two factors that need to be considered. The first is the core that can be made of plastic, steel, iron, aluminum, or other materials. The type of core increases the inductance, its ability to store electric energy. The best type of core is ferromagnetic since it focuses the magnetic field and increases inductance.

The next factor in coil winding is how the wire is wound, a factor that controls the efficiency and conductivity of the coil. The winding is a form of current carrying conductor that is wound around the core, which must be properly insulated and supported to be able to withstand the operational parameters. The primary materials for winding wire are aluminum and copper with copper being the most used due to its excellent conductivity.

Winding of Coils for a Coil Winding

Though the concept of winding is relatively simple, there are a variety of ways that a coil can be wound. An important part of planning a coil winding is the fill factor, or winding factor, which is the of number turns, area of the wire, and the window area. How the winding is completed determines the efficiency and performance of the coil.

All coil windings have more than one coil wound around the core. How the different layers interact is another factor regarding the winding and is a measure of the fill factor. The types of coil winding are wild, helical, orthocyclic, pancake, and toroidal. The key to the winding process is that the wires fit tightly and closely to eliminate air flow or space, which increases the efficiency of the coil.

Types of Coil Windings

Wild or jumble windings are a very common type of winding for mass production of coils. The wires are randomly placed around the core, which creates wider distribution resulting in a wide range of coil resistance. This type of winding leads to poor fill factors. Wild windings are found in relay coils, small transformers, ignition coils, and small motors with a fill factor of 73% to 80%.

Toroid winding is unlike the normal winding of wire around a core. This type of winding has the wire wrapped around the outside of a donut shape where it is evenly distributed around the circumference. Toroid coils are used with low frequency electricity where the coil serves as an inductor.

Orthocyclic windings have a fill factor of 90%. When the wire is being wound, using round wire, the upper layers are carefully placed in the grooves of the lower layer, which limits the amount of air flow and space. The windings must be placed exactly at 60o of the coil circumference to achieve the proper efficiency. If the winding is not done properly, a wild winding is the result.

Helical windings have the wires placed helically on each layer where the direction of the wires change from layer to layer. At first, they are wound left to right for the first layer and then right to left for the second layer. In the process, the wires cross themselves and fill in the gap between the wires. The number of layers for this type of winding is limited to prevent it from becoming a wild winding.

Purpose of Coil Windings

Coil winding is an essential part of the production of electronic equipment and serves as the core for a wide variety of components. The more technical and complex the device, the more likely the winding is done very efficiently and precisely to ensure proper conductance.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services