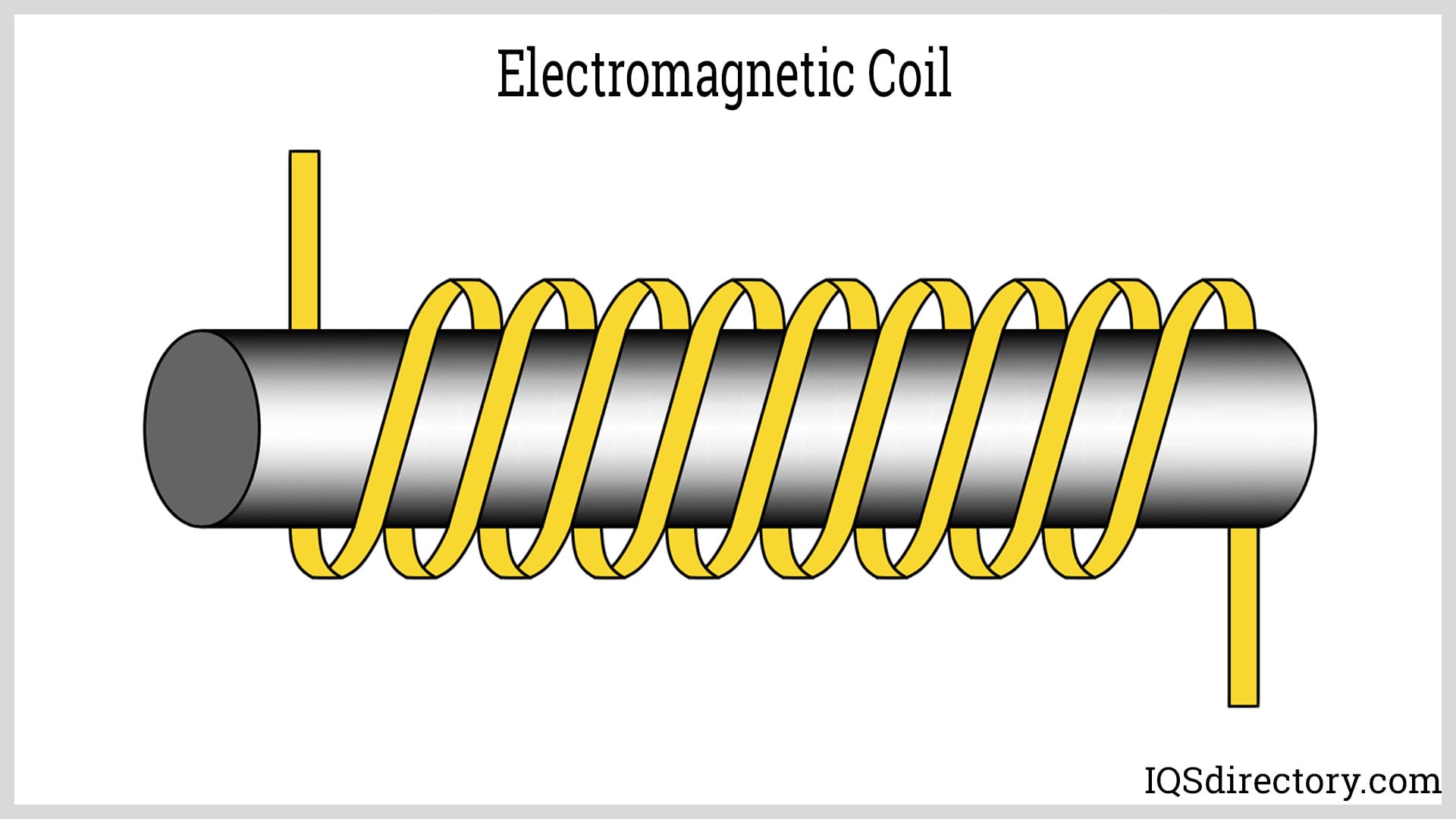

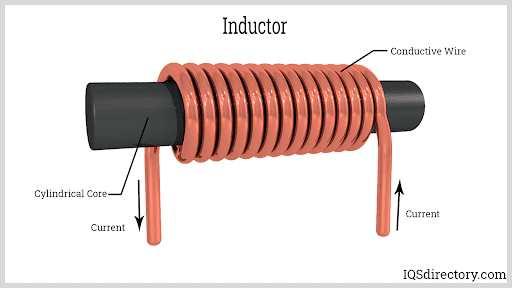

Made from conductive metal wire wrapped or coiled into a specific diameter, encapsulated coils, like all electric coils, are electromagnets or magnets that are only activated to magnetism when introduced to an electrical current. Electric coils provide either movement or electric current transformation through electromagnetism. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

Dufrane has the core expertise to offer custom encapsulations of our custom coils, custom windings and transformers to protect the coils from failure in the most demanding applications. Using techniques such as potting, coating, over- molding, etc. – our coils can be designed to withstand Heat, Extreme Cold, Vibration, Shock, Humidity and moisture, and many other extreme environmental...

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Encapsulated Coil Manufacturers

An outer casing is used on electric coils that require protection from harsh environmental conditions such as moisture, salt, oil or vibration; with nothing to protect delicate copper coils from the elements, an electric coil's conductivity might be easily lost. Encapsulated coils and molded coils solve this problem in overlapping ways: molded coils are enclosed in injection molded or thermoplastic coverings that seal the entire coil unit, while encapsulated coils more often use liquid or thermoformed polymer epoxies.

While these two overlapping types are often the same, molded coils often refers to coils that are encased in hard, hollow thermoformed or injection molded plastic casings; encapsulated coils are often molded into liquid or thermoformed epoxies, causing the coil to become one with its casing.

Encapsulated coils often offer better protection from harsh weather, oil and vibration than molded coils, since encapsulated coils are often dipped or thermoformed into sealing liquid epoxies; epoxies like silicone rubber offer vibration protection that injection-molded casings do not. Encapsulated coils can also be heat-treated after production, a process that sinters the encapsulating plastic part with the molded coil inside, providing superior protection to the coil.

While many encapsulated and molded coils can be cost-effective alternatives to larger, more complicated structures, the tooling costs of manufacturing thermoformed or injection molded plastic casings often rise above the costs of impregnated coils, which have wire directly encased in an epoxy or laminate before it is wound; impregnated coils have no need for outer casings and therefore require little or no tooling.

Manufacturers choose molded coils, encapsulated coils, impregnated coils or custom coils, whichever best fits the application and manufacturing process at hand.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services