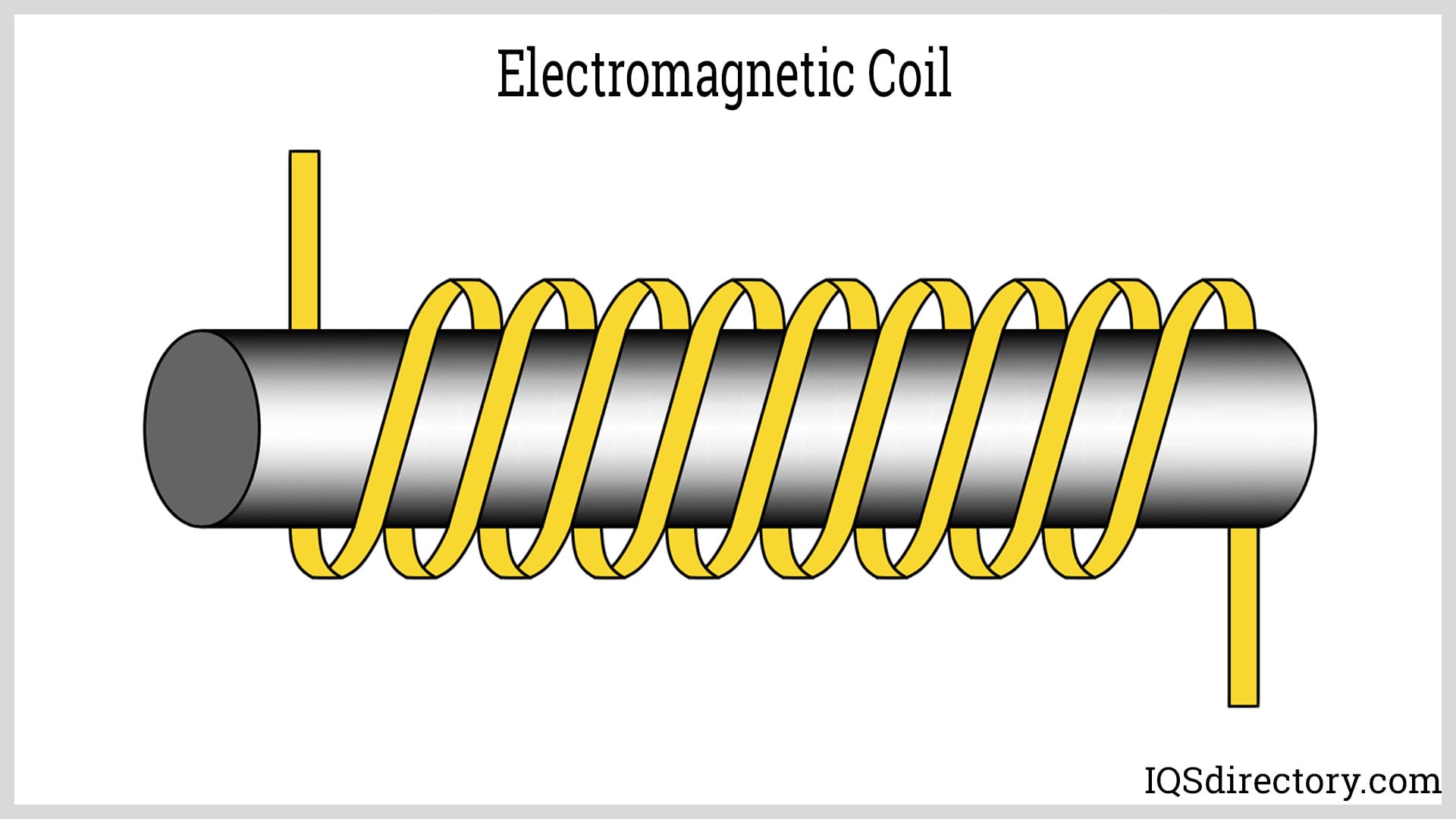

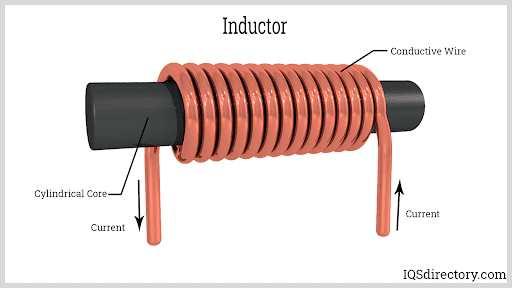

In a rotating machine, the field coils are wrapped around an iron magnetic core that guides the magnetic field lines. The magnetic coil has two parts, a stator and a rotor. The stator is stationary and the rotor rotates within it. The magnetic field lines pass in a continuous loop, called a magnetic circuit, from the stator to the rotor and back to the stator again. Read More…

We are proud of the craftsmanship of our engineers. All of our products are made right here in the United States and we promise that these items are created from high quality resources. Our electrical coils are unique and efficient.

Established in 1973, Classic Coil Company is a Contract Manufacturer of electronic coils. We manufacture coils for a variety of industries; winding wire gauges from 4-58 AWG. We are ISO 9001-2015 certified, ITAR registered and DFARS Compliant. Our Engineering services allow us to assist with design, reduce cost, and increase efficiency in production. Call or visit our website to learn more about...

Since 1962, Torelco has been a supplier of electric coils and transformers of superior quality. We offer custom coils, solenoid coils, ferrite core coils & toroid wound coils to serve a range of industries. Markets served include medical, military, electronics, and industrial. When you work with us, our promise is to build to the exact specifications and meet the custom needs of our customers.

Check out what’s new online at Precision Econowind, manufacturer of the highest quality custom coils at reasonable prices, with on time delivery. Serving the coil industry for over 30 years, we’re experienced with producing loudspeaker & medical industry coils, coils wound on customers’ bobbins/tooling; freestanding, flat wire, edge wound, square, rectangle & shaped coils. Submit your specs ...

At Dufrane Technologies, we take pride in our extensive range of electric coils. Our comprehensive product portfolio encompasses a wide variety of coil types, including solenoid coils, electromagnet coils, induction coils, and more. Whether you require custom-made coils or standard options, we have the expertise and resources to fulfill your specifications with precision.

Triad Magnetics has been in the electric coils industry for over 75 years. Giving us the knowledge and expertise to be one of the best in the industry. We have a wide range of electric coils and inductors as well as the ability to custom engineer and manufacture electric coils to our customer’s needs. Having served the needs of many industries for more than half a century, Triad believes its...

More Field Coil Manufacturers

It consists of a coil wire through which a current flows. Field coils, which energize, may be attached to the stator or the rotor. A rotating machine's magnetic path is characterized by poles, or locations at equal angles around the rotor at which the magnetic field lines pass from stator to rotor or vise versa. The stator and rotor are classified by the number of poles they have. Most configurations use just one coil per pole, but some older or simpler arrangements use a single fuel coil with a pole at each end.

The wire used to wind a field coil must have a low resistance in order to reduce the amount of power it consumes and to reduce the production of waste heat by ohmic heating. This is important because excess heat in the wires is a common cause of failure. Typically, coils are wound with enamelled copper wire, which is sometimes referred to as magnet wire. However, due to increasing cost of copper, field coils are frequently being wound with aluminum.

Some time ago, before the general availability of lightweight permanent magnets, field coils were routinely used in loudspeakers. Today, field coils provide catalyst services for many usages, such as dynamos, alternators, generators, electric motors, starter motors, magnet coils and electric brakes. Non-rotating machines that use field coils include simple electromagnets as well as complex lab instruments such as mass spectrometers and NMR machines.

To meet the complex needs of the market, field coils are available in many different types, including encapsulated, glass taped, tape wrapped, injection molded, transfer molded and loose wound, bobbin wound or self-supported.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services